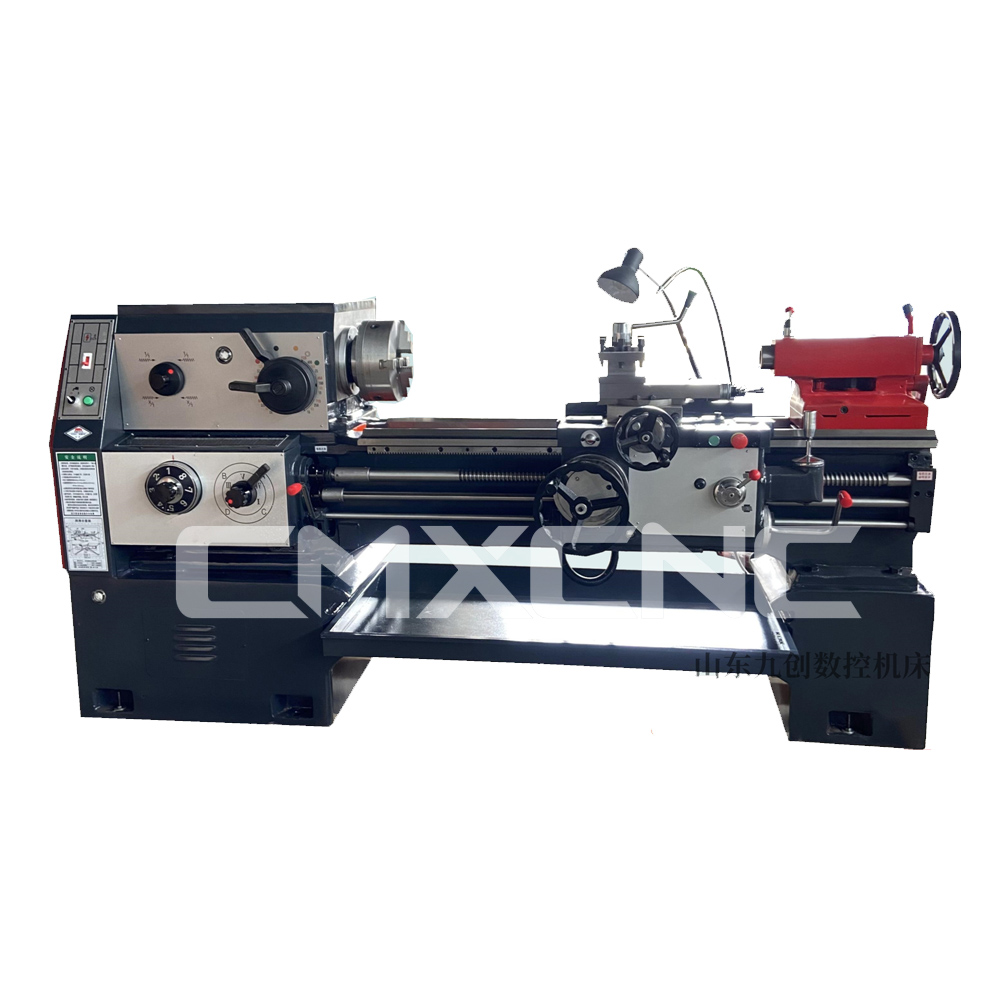

Horizontal Conventional Lathe

Model : CA6140

Maximum workpiece diameter on the bed:400mm

Maximum workpiece diameter on tool post:238mm

Maximum workpiece length: 750mm or 1000mm or 1500mm

1. Machine introduction

The main performance characteristics of CA6140 lathe products:

◆ 6140 conventional lathe headstock and bed, tailstock, pallet and other joint surfaces are manually scraped and ground. The whole machine has been strictly tested to effectively ensure the accuracy and stability of the machine tool.

◆The 6140 conventional lathe is made of high-strength cast iron and added with special materials of copper and chromium. The width of the bed guide rail is 400mm, and the quenching depth of the bed guide rail reaches 4mm, which effectively improves the wear resistance and stability of the machine tool.

◆The headstock lubrication of 6140 ordinary lathe adopts cycloid pump for forced circulation lubrication. In view of the hot weather in the south, the cleanliness and heat dissipation characteristics of the headstock are guaranteed, and the service life of bearings and gears is effectively prolonged.

◆ The main shaft of the machine tool adopts Wafangdian bearing, the through hole of the main shaft is 52/82mm, and the gear of the machine tool is precision ground, which effectively improves the hardness of the gear and reduces the noise of the machine tool.

◆The machine tool adopts domestic brand lead screw, and the screw nut adopts high-quality bronze alloy to ensure wear resistance and precision retention.

◆ The machine tool adopts a four-station high-strength tool holder, and the tool holder size: 25x25mm.

2. Function

◆CA6140 ordinary lathe series ordinary horizontal lathes are suitable for turning inner and outer cylindrical surfaces, conical surfaces and other rotating surfaces, turning various metric, inch, modulus and diameter pitch threads, and can perform drilling and oil grooves. It is a very strong horizontal lathe, which is widely used in batch processing of various shaft and disc parts.

◆ The bed of this series of lathes is wider than ordinary lathes, the guide rail width is 400mm with high rigidity, and the guide rail surface is quenched by medium frequency, which is durable and wear-resistant.

◆The operation of the machine tool is flexible and concentrated, and the slide plate is equipped with a quick-moving mechanism. Using a single handle to visualize the operation, the pleasantness is good.

◆The structural rigidity and transmission rigidity of the machine tool are higher than those of ordinary lathes, and the power utilization rate is high, which is suitable for strong cutting.

◆The machine tool is inspected in strict accordance with the inspection procedures before leaving the factory, and a strong cutting test is performed to ensure that the machine tool has good accuracy stability and processing reliability

Technical Specification

Model Name | CA6140 |

Maximum workpiece diameter on the bed | 400MM |

Maximum workpiece diameter on tool post | 230MM |

Maximum workpiece length | 1000mm |

bed width | 400MM |

shank section | 25X25MM |

Spindle speed range | 10-1400RPM(24types) |

Spindle bore | 52mm |

Spindle hole taper | Mohs NO.6(MT6) |

Feed quantity | 64 types |

Metric thread | (1-192MM)44 types |

Imperial thread | (2-24TPI)21 types |

Modular thread | 0.25-48(Modular 39types) |

warp thread | 1-96DP(37 types) |

Maximum stroke of tailstock spindle | 150MM |

Tailstock Spindle Diameter | 75MM |

Tailstock spindle hole taper | Mohs NO.5(MT5) |

main motor | 7.5KW |

Dimension | 2350X1037X1650 |

Weight | Gross Weight Net Weight |

X1500 | 1900 1800 |

4. List of accessories

List of accessories | |||||

No | Part Name | Specification | Unit | Qty | |

1 | Chuck | pc | 1 | ||

2 | Chuck wrench | pc | 1 | ||

3 | Tool holder wrench | pc | 1 | ||

4 | Press knife wrench | pc | 1 | ||

5 | Center | pc | 1 | ||

6 | Hex Wrench | pc | 1 | ||

7 | Solid Wrench | pc | 1 | ||

8 | center frame | pc | 1 | ||

9 | Tool Holder | pc | 1 | ||

10 | Iron Pad | pc | 1 | ||

11 | Oiler | pc | 1 | ||

12 | Manual | pc | 1 | ||

13 | Warranty Card | pc | 1 | ||

If you need any more information. Please contact us .

Contact: Ivy Yu

Phone: 86-13757734757

E-mail: sales@caminix.com

Whatsapp:0086-13757734757

Add: Building 38, 1st Xu'an Industrial Park,Gaohu,Qingtian,Lishui,Zhejiang,China

We chat